The efficiency of the airflow is a critical factor in the operation of any air conditioning or cooling system. The way the air passes through the heat exchanger directly affects the heat transfer rate, pressure drop, and overall energy consumption of the system. Traditional ribbed tube coils have long been the standard, but their design limitations, especially with regard to airflow resistance and uneven distribution, can hinder optimal performance. Microchannel heat exchangers, on the other hand, are designed to solve these problems directly, providing improved airflow dynamics, resulting in a real increase in efficiency.

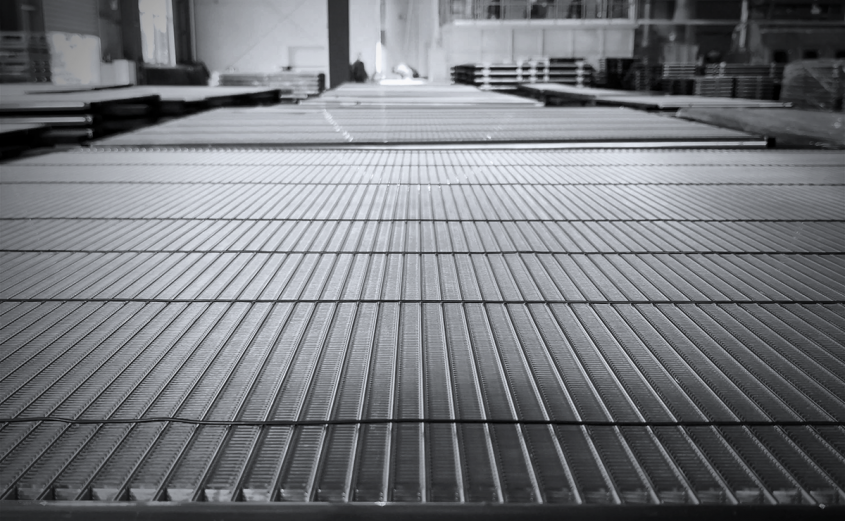

One of the key reasons why microchannel water coil are superior to traditional designs is their internal structure. Instead of round copper tubes with aluminum fins spaced apart, microchannel technology uses flat multi-channel aluminum tubes combined with precision-engineered fins. This configuration reduces air resistance while increasing the effective heat exchange surface area. As a result, a more uniform air flow is provided throughout the coil, which increases thermal performance without the need for additional fan power.

The advantages of this design are particularly noticeable in roof installations, split systems and complete air conditioning equipment, where limited space often leads to compact placement of coils. In such cases, microchannel heat exchangers help maintain a constant air flow even in cramped conditions, reducing the risk of hot spots, temperature stratification, and inefficient cooling cycles.

Optimized edge geometry improves productivity

In addition to the location of the pipes, the design of the fins plays a crucial role in improving the efficiency of the airflow. Modern microchannel coils are equipped with advanced blinds and corrugations that allow air to pass through the coil matrix more efficiently. These features not only reduce turbulence, but also increase the rate of heat absorption and removal, ensuring constant air contact with the coil surface.

Some models use variable fin spacing to provide different airflow speeds, allowing engineers to fine-tune performance based on specific system requirements. For example, in environments with high static pressure, such as VAV systems or industrial process cooling systems, the smaller fin spacing helps maintain heat transfer without overusing fan energy. In contrast, lower density configurations are ideal for applications where noise reduction and ease of cleaning are priorities.

This level of customization contributes to better system integration and ensures that each replacement of the carrier microchannel coil delivers the expected performance improvements and energy savings. Business leaders who switch to older copper-aluminum coils often report shorter compressor operating times and lower fan power consumption, which is a direct result of improved airflow control.

Reduced pressure drop and system deformation

Another important advantage of the microchannel design is its effect on the pressure drop in the coil. Traditional coils tend to create higher resistance due to uneven flow paths and large obstacles in the tubular-ribbed matrix. Over time, this forces the fans to work harder, consuming more energy and shortening the life of the components.

Microchannel heat exchangers minimize this problem by providing a smoother and laminar air flow. Due to fewer breaks and a more open design, air passes through the coil with less resistance. This not only increases the efficiency of the system, but also reduces the mechanical load on the fans and motors, resulting in longer maintenance intervals and lower maintenance costs.

For technicians working with legacy Carrier installations, replacing outdated coils with modern carrier microchannel coil replacement options can significantly improve airflow efficiency without having to make significant changes to the existing system. Many modernization solutions are designed to take into account the size of the original equipment, while providing all the advantages of microchannels.

In conclusion, the effect of the microchannel design on the efficiency of the airflow should not be underestimated. Optimized rib geometry, reduced pressure drop and improved heat transfer – all these improvements have a direct impact on reduced energy consumption, quiet operation and durability of the system. The introduction of microchannel technology, whether as part of a new installation or an upgrade, represents a smart investment in more intelligent and sustainable air conditioning and cooling systems.